Introduction

Once the Main Dimensions and Hull Form have been fixed

consideration can be given to the General Arrangement.

Normally this will be done by means of the drawing of a

small scale General Arrangement plan. A scale of 1 to 200 is quite suitable

although a larger scale may be more appropriate for small ships. The only

boundaries which have been fixed so far are the hull surface and any deck lines

which affect freeboard. The remaining space boundaries in the ship remain to be

fixed.

A major decision is to determine the position of the

machinery space. In a light condition the density of the machinery space and

the accommodation, taken together, is greater that the rest of the ship's

length.

In a loaded condition the reverse is truer. This is

important when considering trim.

- Division into compartments (tanks, engine

room, holds)

- Location of bulkheads

- Location and arrangement of superstructure

- Parts of the

equipment (winches, loading gear, bow thruster, life boats).

- Dimensions (Length, Breadth, Draft)

- Volumes of the holds (Cargo Capacity Grain

& Bale)

- Tonnage

- Deadweight

- Engine power

- Speed (Service Speed)

- Class

Important Decisions for Planning of General Arrangement Drawing

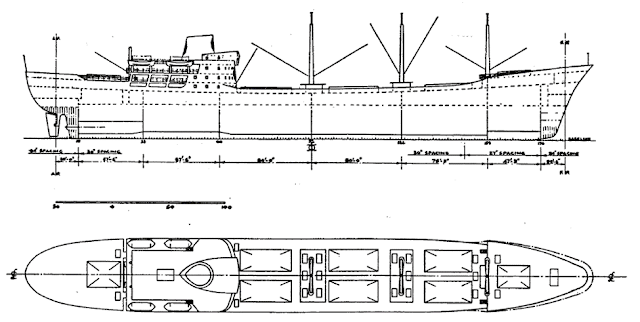

GA of a dry cargo

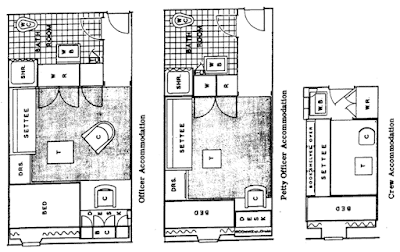

Crew accommodation plan

1: Trim

A level keel trim is usually specified for the full load

condition with homogeneous cargo. This is mainly to make the best use of the

available depth of water in port - usually a restrictive item.

Some designs either specify a design trim or must accept

one. There are ships in which the weight distribution is so extreme that

balance between the LCG and LCB can only be achieved by using trim to make a

radical adjustment to the sectional area curve.

Tugs and fishing vessels are common examples where the need

for propeller immersion also plays its part and warships often have this

feature.

As ships tend to trim by the bow relative to their static

trim when running at normal speeds, no bow trim at all can be permitted at

rest.

Usually cargo is disposed to ensure some stern trim in most

sea-going conditions. Steering and directional stability can be upset by bow

trim.

In the initial design stages trim is mainly controlled by

the location of the machinery space relative to the cargo holds. Provision of

ballast spaces including the peak tanks gives some control over trim but

carrying ballast is a waste of deadweight and may impose undesirable stresses.

Reasonable trim must also be maintained during cargo working

at intermediate ports. In the case of the traditional general cargo vessel this

was no easy thing to do unless the machinery space was amidships.

2: Location of the Machinery Space

The most common position for the

machinery space in modern cargo ships is completely aft. Trim problems are

severe in general cargo vessels and cannot be solved without ballast tanks

forward to use in the light condition. Sometimes it is difficult to avoid bow

trim when loaded. This location is suitable for, and typical of, ships which

carry homogeneous cargoes such as tankers and bulk carriers, especially when

the cargo is denser than seawater since their weight distribution can be

controlled to solve trim problems. While the best part of the ship is given to

the cargo holds the machinery space may require more

length than expected in order to

accommodate the auxiliary machinery. The use of segregated ballast tanks in

tankers or a floodable hold in bulk carriers provides control of draught, trim

and bending moment if carefully sized and located.

In large high-speed and

high-powered container ships the machinery space is often situated in the

three-quarters aft position. Although this splits the container stowage area

into two parts it allows the machinery to be installed in a fairly full part of

the ship. Trim can be kept under control with only a modest requirement for

water ballast and bending of the hull girder between loaded and light condition

may be minimized.

3: Storage of Liquid

Once the Position and size of the

machinery space has been decided then attention can be turned to tank spaces.

Normally these are confined to double bottoms but deep tanks may be arranged

for additional water ballast in the Fore and After Peaks for trim or near

amidships to control hull girder bending.

Engine Room double bottoms will

first be allocated to Lubricating Oil storage, drain and sump tanks together

with cofferdams to ensure there is no Lub. Oil/Salt Water interface which could

leak and cause contamination.

While main propulsion engines

will be happy running on fairly heavy fuel oil, diesel generators normally

require the lighter Diesel Oil. This should be stowed reasonably close to the generators.

Ideally, the tanks for fuel oil can then be allocated with a view to ensuring

that the LCG of the fuel is forward of the LCG of the loaded ship so that as

fuel is consumed the ship will not tend to trim by the bow.

Modern practice, driven by

pollution control requirements, discourages the use of double bottom tanks for

fuel storage. Thus the only way to have control over fuel LCG is to fit deep

tanks forward and aft of the cargo holds and accept long filling and supply

lines to/from the forward tanks. The alternative of only having fuel tanks aft

has the consequence that a significant stern trim in the Departure condition

will be followed by a significant bow trim in the arrival condition.

In addition to the storage tanks,

space also needs to be found for settling tanks and daily service tanks to

satisfy the needs of the main and auxiliary machinery. These are usually located

within the boundaries of the machinery space. Actually finding the space for

them may not be a task for the Naval Architect but the Weight & centre of

gravity of their contents is a legitimate concern.

Water ballast is required to give

adequate propeller immersion in the lightest seagoing condition and to ensure

that the minimum draught forward is sufficient to avoid excessive slamming.

While many ships now distil their

own Fresh Water from sea water a limited storage capacity is necessary for use

when the ship is in polluted or coastal waters where distillation is not

possible.

Holding tanks for sewage and

waste water are necessary to avoid marine pollution. They are small in a cargo

ship but of significant size in passenger ships.

4: Cargo Holds

5: Hatchway

Large hatchways assist easy cargo

working but hatch widths are restricted by the need to maintain not only the

cross sectional area of deck material for structural reasons but also the shelf

space at the tween deck levels. The ingenious use of twin hatches, side by

side, can facilitate both good cargo working and the containment of grain

cargoes in a general cargo ship.

The length of hatches is

constrained by the length of deck taken up by cargo gear and hatch cover

stowage. General cargo ships usually have the capability of carrying some

containers within the line of hatches and this will lead to hatch dimensions

tending to be a multiple of container lengths and widths with an allowance for

clearance between them.

Flush hatches are clearly

desirable for ease of cargo working but in general load line requirements will

prohibit or severely penalise the ship for their use on a weather deck.

6: Accommodation/Superstructure Arrangement

Usually the accommodation is

sited above the machinery space and around the engine casing to minimize

interference with cargo operations. The result is a short, high superstructure

giving good forward visibility but possibly compromising stability. A good

arrangement is largely a matter of common sense, experience and foresight. Any

difficulties which arise in service should be noted and avoided in the next

design.

Minimum manning scales and

minimum standards for accommodation are laid down in regulations. Virtually

every crew member nowadays will have a single cabin and officers may well have

suites with dayroom, sleeping cabin, bathroom etc.

Automation has a continuing

influence, gradually reducing crew numbers and further significant changes may

take place in the coming decades.

Remember that the accommodation

is where the seafarer lives out his/her life. It is his/her home for long

periods as well as his/her place of work. There must be public space to

socialize in and private space as a retreat from work.

7: Length of Machinery Space

Assuming that diesel propulsion

is to be adopted (and it usually is) then the length of the machinery space is

governed either by -

(1) The Main Engine, Gearbox (if

fitted) and Thrust Block

(2) The Generators

An end clearance of one or two

frame spaces should be added to the neat length. Care must be taken to ensure

that there is sufficient space for the auxiliary machinery. Ideally these

should be sited on the tank top, particularly those requiring a solid

foundation to minimize vibration e.g. Generators and Compressors. Flats can be

fitted to provide additional area but often cannot be made stiff enough to

support major auxiliaries.

Technological change tends to make the machinery grow in complexity but to shrink in size and so machinery spaces tend to become smaller over time. However engine maintenance is an important consideration for the effective operation of the ship. Too compact an engine room may make maintenance more difficult and even more expensive. Access to the equipment and removal routes for parts from them should be adequate.

Minimum Requirements for Crew

Accommodation

Segregation into Officers, Petty

Officers and Ratings is still common in the Merchant Navy although it becomes

harder to sustain as crews become smaller. A ship which had 30 of a crew thirty

years ago would be designed to run with half that number now. Justifying

separate facilities for each grade becomes very difficult.

- a) Deck and Engineer Officers. In Single or double cabins (Master and Chief Engineer should each have an individual cabin). Bathroom with one bath or shower and one wash basin for every six persons. Separate dining saloon and smoke room.

- b) Petty Officers. Cabins and Washing facilities as for officers. Separate messroom. (1m2 per person)

- c) Engine Room Hands. Separate sleeping and dining accommodation (but numbers sharing cabins not specified). Bathrooms as for officers.

The International Labour Organization (ILO) recommends minimum floor areas per

person in sleeping rooms as -

3.75 m2 in ships of 1000-3000 tons,

4.25 m2 in ships of 3000 – 10000 tons and

4.75 m2 in ships over 10000 tons.

(Tons are gross tons; a volumetric measure)

Where two ratings share a cabin

the above figures are reduced by 1 m2 per person.

- d) Deck Hands. Cabins, dining accommodation and bathrooms as for Engine Room Hands. Crew’s smoke room shared with Engine Room Hands.

Many ships offer higher standards than these such that all crew have single cabins with ensuite bathrooms and perhaps double beds so that wives can travel on some voyages. An officer’s single cabin could reach 21 m2 with bathroom and crew’s single cabin 16 m2 also with bathroom.