SHAHBAZPUR GAS FIELD

1. Description of Field

Introduction

Shahbazpur Gas Field was discovered by BAPEX (Bangladesh Petroleum Exploration and Production Company Ltd) in 1995 at Bhola, Bangladesh. The production was commenced in 11th May, 2009. In the earlier stage of production, the plant was based on LTX units till late 2014. In 2015, the plant was changed to TEG Dehydration unit base from LTX unit base due to the high condensate and water production rate. Till now, it has the highest production rate compared to the other gas fields owned by BAPEX.

Objective

- To supply gas to local residents in Bhola

- To get attached with the national energy grid of Bangladesh

- To supply gas to the 220 MW power plant which is under planning (Project Name: Bangladesh Bhola IPP)

Salient Features

|

1. |

Location |

: |

Borhanuddin, Bhola |

|

2. |

Number of Wells |

: |

04 |

|

3. |

No of Producing Wells |

: |

03 |

|

6. |

Daily Production |

: |

50 MMSCF (10th January, 2019) |

|

7. |

Type of Process Plant |

: |

Glycol Dehydration |

|

8. |

Capacity |

: |

70 MMscf/D (2 Glycol Dehydration

Tower, Capacity of 35 MMscf/D each) |

|

9. |

Cumulative Production |

: |

39.03 BCF (Dec’17) |

|

10. |

Total Reserve |

: |

1.6 TCF |

The

Shahbazpur gas field is located in Foredeep area of Bengal basin or can be said

more precisely in the Hatia trough. The Foredeep part of the Bengal basin is

located towards west from eastern fold belt where intensity of folds decreases

continuously and Foredeep unit is characterized by only mild or no folding. So,

the sedimentary layers are generally horizontal to sub horizontal and are free

from major tectonic deformation in the Foredeep area. This unit covers the

central part of the basin and is represented by river to delta plain topography

at the surface.

Table 1.2.1: Stratigraphy and Lithology in Shahbazpur Structure

|

Depth |

Age |

Group |

Sequence |

Lithology |

|

0-480 |

Recent |

Alluvium

(480) |

Loose

unconsolidated sand with occasional clay |

|

|

480-1505 |

Pleistocene |

Dupi

Tila |

SB-I

(1025) |

Shale

with occasional occurrence of interbedded sandstone and siltstone |

|

1505-2010 |

Pleistocene-

Pliocene |

Tipam |

SB-II

(505) |

Shale

and Sandstone |

|

2010-2750 |

Plio-

Miocene |

Surma |

SB-III

(740) |

Sandstone

and shale |

|

2750-3631 |

Miocene |

SB-IV

(881) |

2. : Reservoir and Well Condition

Reservoir Condition

The Shahbazpur structure is a subsurface anticlinal structure situated in the middle of the Bhola Island in the northern margin of Hatia trough of Bengal Foredeep. The Hatia trough is bounded by the Chandpur-Barisal high in the northwest, and by the Chittagong-Tripura Fold Belt in the southeast. The alignment of the NW-SE trending oval shaped Shahbazpur structure is parallel to the Kutubdia structure which is located in Bay of Bengal to the south. Shahbazpur Structure is surrounded by Muladi Structure to the Northwest and Kutubdia Structure to the Southeast. The structure started growing probably during Late Miocene and its acme of development took place during Mio-Pliocene sedimentation and ended in Pleisto-Pliocene time (Mondal et al.9). This structure is relatively 69.4 m higher than the Kutubdia structure. The amplitude of the structure increases with depth. There is no surface expression of the Shahbazpur structure

Reservoir Depth: 3480 m

Reservoir Pressure: 5400 Psi

Reservoir Temperature: 195 F

Well

Condition

Casing Diameter: 7 in

Table 1.3.1: Well Conditions of Shahbazpur Gas Field

|

Well

Name |

Type

of Well |

Condition |

Wellhead

Pr (psi) |

|

Well-1 |

Vertical |

Under

Workover |

4000 |

|

Well-2 |

Directional |

Under

Production |

3600 |

|

Well-3 |

3800 |

||

|

Well-4 |

4200 |

Figure 1.3.1: Well-03 of Shahbazpur Gas Field

3. : Fluid Properties

Sales Gas:

The sample was tested at 94 F and 540 psi

by BAPEX Lab.

Table 1.4.1: Molecular Composition

|

Components |

Mol% |

Wt% |

|

Nitrogen |

0.473 |

0.766 |

|

Carbon Dioxide |

0.809 |

2.056 |

|

Methane (C1) |

93.384 |

86.515 |

|

Ethane (C2) |

4.152 |

7.212 |

|

Propane (C3) |

0.785 |

2.000 |

|

iso-Butane

(i-C4) |

0.233 |

0.782 |

|

n-Butane

(n-C4) |

0.083 |

0.280 |

|

iso-Pentane

(i-C5) |

0.026 |

0.110 |

|

n-Pentane

(n-C5) |

0.013 |

0.052 |

|

Hexanes (C6) |

0.012 |

0.061 |

|

Heptanes+ (C7+) |

0.029 |

0.166 |

|

Presence of Hydrogen Sulfide |

Absent |

|

4. : Process Flow Diagram

The

process flow diagram and site view of the process plant, Shahbazpur Gas Field

are given below:

Figure 4.5.1: Process Flow Diagram of Shahbazpur Gas Field

Figure 1.5.2: Site View of Process Plant of Shahbazpur Gas Field

5. : Control System

In

this field, the operations are controlled by Distributed Control System

(DCS). Still, there are some operations controlled manually to reduce the

complexity of the plant.

Distributed Control System (DCS)

A distributed control system (DCS) is a computerized control system for a process or plant usually with a large number of control loops, in which autonomous controllers are distributed throughout the system, but there is central operator supervisory control.

Basic

Elements of DCS: There are three basic

elements of DCS. These are:

- Engineering PC controller

- Communication Media

(Transmission Cables)

- Distributed Controller and Logic Unit

Principle of Working: These distributed controllers are connected to both field devices and operating PCs through high speed communication networks as shown in Figure 4.6.1. Discrete Field devices such as sensors and actuators are directly connected to input and output controller modules through communication bus. These field devices or smart instruments are capable of communicating with PLC’s or other controllers while interacting with real world parameters like temperature, pressure, etc. Controllers are distributed geographically in various section of control area and are connected to operating and engineering stations which are used for data monitoring, data logging, alarming and controlling purpose via another high speed communication bus.

Figure

1.6.1: Architecture of DCS Panel

6. : Process Units

There are two process plants (Plant-A, Plant-B) and each plant has same process units. These are:

- Three

Phase Separator

- Header

- Water

Bath Heater

- Two

Phase Separator

- TEG

Dehydration Tower

- Sales

Gas Scrubber

- Condensate

Flash Separator

- CPI Unit (Corrugated Plate Interceptor)

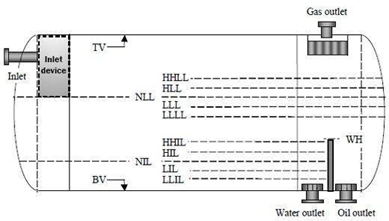

Three Phase Separator:

A vessel that separates the well fluids into gas and two types of liquids: oil and water is called a Three Phase Separator. A three phase separator can be horizontal, vertical or spherical. This type of separator is commonly called a free-water knockout because its main use is to remove any free water that can cause problems such as corrosion and formation of hydrates or tight emulsions, which are difficult to break.

Figure 1.7.1: Three Phase Separator

In

a gathering system, Header is a pipe arrangement that connects flow lines from

several wellheads into a single gathering line. A header has production and

testing valves to control the flow of each well, thus directing the produced

fluids to production or testing vessels. Individual gas/oil ratios and well

production rates of oil, gas and water can be assigned by opening and closing

selected valves in a header and using individual metering equipment or

separators.

Figure

1.7.2: Production Header

Water

Bath Heater:

The

primary applications for Water Bath Heaters include:

- Heating Natural Gas prior to

pressure reduction manifold to prevent freezing or expansion

- Hydrate Prevention

- Increasing separation efficiency

by heating processed upstream fluid

The

heater consists of three main components:

- Shell

- Fire Tube

- Process coil

Two

Phase Separator:

A

vessel that separates the well fluids into gas and total liquid is called a Two

Phase Separator. A two phase separator can be horizontal, vertical or

spherical. The liquid (oil, emulsion) leaves the vessel at the bottom through a

level-control or dump valve. The gas leaves the vessel at the top, passing

through a mist extractor to remove the small liquid droplets in the gas.

Figure

1.7.4: Two Phase Separator

The

purpose of a glycol dehydration unit is to remove water from natural gas and

natural gas liquids. When produced from a reservoir, natural gas usually

contains a large amount of water

and

is typically completely saturated or at the water dew point. This water can

cause several problems for downstream processes and equipment. At low

temperatures the water can either freeze in piping or, as is more commonly the

case, form hydrates with CO2 and hydrocarbons (mainly methane hydrates).

Figure

1.7.5: Glycol Dehydration Tower

The

purpose of a gas scrubber is to eliminate harmful particulates and liquid

hydrocarbons from natural gas. A natural gas scrubber system works by using

particle filters, coalescers, mesh pads, and other devices to remove pollutants

from the gas stream. This type of gas scrubbing is the preferred way to ensure

that natural gas is clean and dry for industrial use.

Condensate Flash Separator:

Flash

Separator separates condensate from water and sends the condensate part to the

storage tank. The water portion then goes to the CPI unit.

CPI Unit:

Process

Group CPI Units are designed to remove free oil and suspended solids from water

as a primary stage of water treatment and utilize plate packs as the main

separation device. The plate packs are designed with specific spacing and

alignment to allow solids to settle and fall to the bottom while simultaneously

allowing oil drops to rise and coalesce, thereby reducing the oil and solids

loading from the downstream water treatment train and smoothing out flow

slugging.

7. : Equipments

Globe

Valve:

A

globe valve, different from ball valve, is a type of valve used for regulating

flow in a pipeline, consisting of a movable disk-type element and a stationary

ring seat in a generally spherical body.

Butterfly

Valve:

A

butterfly valve is a valve that isolates or regulates the flow of a fluid. The

closing mechanism is a disk that rotates.

Non-Return

Valve:

A

non-return valve allows a medium to flow in only one direction. A non-return

valve is fitted to ensure that a medium flows through a pipe in the right

direction, where pressure conditions may otherwise cause reversed flow.

Pressure

Control Valve (PCV):

A

PCV valve that's supposed to regulate the flow of these gases is the heart of

most PCV systems (some newer vehicles don't have a PCV valve). The PCV valve

routes air and fuel from the crankcase back through the intake manifold to the

cylinders rather than allowing them to escape into the atmosphere.

Temperature

Control Valve (TCV):

A

temperature control valve is just like any other control valve. The only

difference is that the control valve helps to maintain the temperature of

a desired process at a specific level.

Level Control Valve (LCV):

A

level control valve or altitude control valve is a type of valve that

automatically responds to changes in the height of a liquid in some storage

system.

Plug

Valve:

Plug valves are valves with cylindrical or conically tapered plugs which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going sideways through the plug,

Measuring

Tape:

It

is used for measuring the water and condensate level in the condensate storage

tank. Water finding paste is placed on the measuring tape and then the

measuring tape is inserted into the tank. When it finds water it changes its

color and thus it indicates the water level where the color is changed. Once

the water level is read, the condensate level is calculated from the previous

record of condensate level comparing with the water level and the total height

of the storage tank.

Figure 1.8.5: Reading Water and Condensate Level by Measuring Tape

Kimray

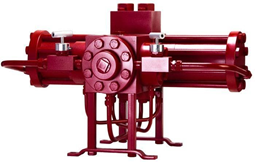

Pump:

It

is such a pump that uses energy exchange theory and doesn’t need any external

energy to start. So it has a great use in industrial purpose where external

power is quite difficult to manage. It generally starts by differential

pressure. It is mainly used for Glycol Regeneration process.

Figure

1.8.6: Kimray Pump

I2P

Converter:

A “current to pressure” converter (I/P) converts an analog signal (4 to 20 mA) to a proportional linear pneumatic output (3 to 15 psig). Its purpose is to translate the analog output from a control system into a precise, repeatable pressure value to control pneumatic actuators/operators, pneumatic valves, dampers, vanes, etc.

Figure 1.8.7: I2P Converter

Barton

Chart Planimeter:

Barton

chart recorders are the industry standard

for accurate, reliable measurement and recording of

pressure, differential pressure, and temperature in a wide variety of

applications. In addition, DP models

utilize Barton’s rupture-proof bellows DPU as

the actuating unit with features like overrange protection and pulsation

dampening.

Components: 1) Case 2) Chart Drive 3) NuFloTM Chart 4) Recording Mechanism 5) Pressure Element and 6) Thermal System

Figure 1.8.8: Barton Chart Planimeter

8. : Pipe Schedule, Fittings and Valve Ratings

Pipe

Schedule:

There

are 5 pipe schedules used in the process plant. These are: XXS, 160, 120, 80

and 40.

Valve

Rating:

There

are 4 differently rated valves used in the process plant. These are: #2500,

#1500, #600

and

#150.

Table

1.9.1: Maximum Allowable Non-Shock Pressure

(Psi)![]()

|

Pr

Class (lb) Temp

(F) |

#150 |

#600 |

#1500 |

#2500 |

|

-20

to 100 |

285 |

1480 |

3705 |

6170 |

|

200 |

260 |

1350 |

3375 |

5625 |

|

300 |

230 |

1315 |

3280 |

5470 |

|

400 |

200 |

1270 |

3170 |

5280 |

9. : Flow Calculation

Flow

Calculation by Digital Meter:

Rate

of Flow, Qh = C`√(hwPf) in MMSCF/d

Where,

C` = Fb * Fpb *Ftb * Fg * Ftf * Fr * Y * Fpr * Fm and Fb = Basic Orifice Flow

Factor

Fpb

= Pressure Base Factor

Ftb

= Temperature Base Factor Fg = Specific Gravity Factor

Ftf

= Flowing Temperature Factor Fr = Reynold’s Number Factor

Y

= Expansion Factor

Fpr

= Supercompressibility Factor Fm = Manomatric Factor

Input

Variables: 1. Pipe Inner Dia (ID) in inch

2.

Orifice Inner Dia (ID) in

inch

3.

Specific Gravity of Gas

4.

Flowing Temperature (in

F)

5.

Gauge Pressure (in PSI)

6.

Avg Differential Pressure

(in H2O inch column)

Optimum

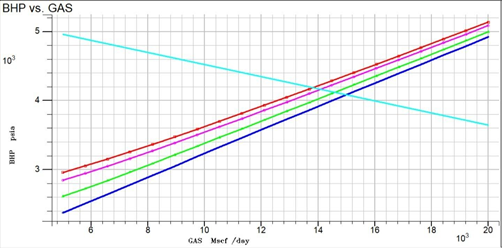

Flow Calculation by ECLIPSE:

For

well no-2, the officials of SBZ gas field have manually found that considering

all factors and variables the optimum flow rate is around 14 MMscf/d. But here,

we have done an experimental simulation of optimum flow rate using ECIPLSE

software and it came out 14.6 MMscf/d which is close to the field result.

Input Variables:

Tube

Dia = 4.5 in Casing Dia = 7 in

WGR

= 1.1229 bbl/ Mscf CGR = 0.12 bbl/ Mscf

PI

= 11.42 Mscf/ d. psi SG of Water = 1.00

SG

of Condensate = 0.9 SG of Gas = 0.5992

Max

Flow Rate = 20 MMscf/d Min Flow Rate = 5 MMscf/d Reservoir Pr = 5400 psi

Table 1.10.1: Temperature Data

|

Measured

Depth (ft) |

TVD

(ft) |

Temperature

(F) |

|

0 |

0 |

155 |

|

11480 |

11480 |

195 |

Result:

Optimum

Flow Rate is 14.6 MMscf/d at THP = 350 psi

Figure

1.10.1: BHP vs Flow Rate Curve with IPR of Well

No-02

10. : Consumer

There are four major consumers of the sales gas produced by Shahbazpur Gas Field. These are:

Table 1.11.1: Consumers of Sales Gas

|

Consumers |

Capacity of Power Plant (MW) |

Daily Demand (MMscf) |

|

Aggreko |

95 |

20-26 |

|

PDB |

225 |

33 |

|

PP Venture |

34 |

8 |

|

Household |

N/A |

0.7-1 |

11. : Health and Safety Management

Fire Fighting System:

For

fighting system, the plant was installed following equipments:

1. Smoke Detector

2. Fire Alarm

3. Jockey Pump

4. 2x Diesel Pump

5. Fire Extinguishers (CO2, Dry powder, Fire bucket etc.)

There is a fire pond for spraying water to deal with fire. It has almost 6000 m3 of water.

Conclusion

- Preparation of EPC Enquiry Documentation

- Bid Evaluation

- Contract Negotiations & Award

- Oversee Contractor’s Detail Design

- Field Supervision

- Progress Monitoring and Control

- Contractor Invoice Approval

Clearly, It is an engaging blog for us which you have provided here about PP Butterfly Valve This is a great resource to enhance knowledge about it. Thank you.

ReplyDeleteI am very thankful to you that you have shared this information with us. Read more info about Pvc Pipe Fittings Online. I got some different kind of knowledge from your web page, and it is really helpful for everyone. Thanks for share it.

ReplyDeleteYou've supplied us with an interesting article. This is a fantastic resource for expanding your understanding of the subject. Thank you very much. test and tag services Melbourne

ReplyDeleteI'd like to express my gratitude for sharing such an excellent article. The article is instructive because it offers some useful information. Thank you for sharing it with us. Continue to post. test and tag services brisbane

ReplyDeleteI'm grateful for the information you've provided in this article. You have some fantastic photographs in the preceding article. Thank you so much for sharing it. Keep up the good work. rcd testing

ReplyDelete