a) Patterns

b) Molding

c) Cores

Theory:

The convenience enjoyed in the modern home and society depends largely on foundry products. As we leave our homes to go about our daily work, we find that castings produced in the foundry play a most important part in our lives. Our modern land, sea and air transportation systems depend upon castings for their operation. On an average, an automobile has 600 pounds or more of cast metal parts in its construction. Modern communication and lighting system would be impossible without castings.

The electrical machinery group and automobiles are the heaviest uses of iron castings, while heavy tonnages into cast iron pipe and car wheels. Railroads take a large percentage on steel castings. Castings are used very extensively in heavy machinery. Non-ferrous castings of the brass and bronze type go largely into the automobile industry and machine tool group. Aluminum and manganese casting are used where lightness is required.

The industry’s product, casting enters into every field in which metals serve man. Castings are used in transportation, communication, construction, agriculture, and power generators. In aerospace and atomic energy applications and in other activities are too numerous to describe.

Modern civilization would not be so far advanced as it is today if it were not for the foundry and its products. The foundry industry is a progressive one, always, looking ahead and as it improves, so will civilization.

Foundry in metals:

A metal casting is made by allowing liquid metal to solidify in a cavity (Mold) of desired shape. Metal casting is usually carried out in a foundry. The first castings were made of brass and bronze. Then came cast iron. Now many metals or alloys of metals are used, the principle type being iron, brass and bronze, malleable cast iron steel, aluminum and magnesium.

Most castings are sand casting made by pouring molten metal into a form (Mold). The mold is made in a box (flask) of wood or metal that is filled with packed, rammed sand containing a cavity formed by a pattern. Some castings are made in metal mold.

The foundry men use a pattern made of wood, metal, plastic etc. shaped like the desired shape of product for castings. Some castings are hollow. These hollows are made by placing cores in the mold. Cores are sand formed in a box that shapes the core to the form of the hollow casting. Core sand is mixed with a binder like linseed oil, molasses, resin, fish oil etc. The core held in shape by the binder is then baked in an oven to dry thoroughly to make it easy to handle.

Moldings:

The

making of molds required great care and skill, since castings of tin must meet

close tolerances as to size and other physical and chemical properties. In hand

made molds, particular skill and knowledge are necessary for-

- ‘Ramming up’ a sand mold to the right hardness.

- Placing ‘Runner’ and ‘Riser’ and ‘Cutting Gate’ in the sand through which the molten metal would be poured into the mold cavity.

- Cutting and shaping the sand around the pattern in the bottom part of the mold (drag) so that the top part (cope) of the mold would be lifted from the drag without having the sand tear or break in the process.

- Patching any torn parts of the mold so that the casting when poured would be a true reproduction of the original pattern.

- Settings of cores if it is required.

- Pouring molten metal into the cavity of the mold.

TOOLS AND EQUIPEMENT FOR MOLDING WORK

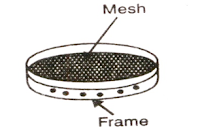

RIDDLE: A riddle, as shown in Fig.1, has a standard wire mesh fixed into a circular or square wooden frame. It is used for cleaning the molding sand. The riddles are specified by the diameter of the frame and the mesh number. When large volumes of sand are to be cleaned, then power operated riddles are used.

RAMMER: A hand rammer generally made of wood is used to pack the sand in the mold. It has got two ends, one end is sharp and the other end is blunt. The sharp end of the rammers called the PEEN END which is used to pack the molding sand through the corner of the molding flask and the other end is called the BUTT which is used to pack the sand finally.

Figure-2:

Rammer

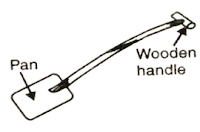

TROWEL: The trowels, as shown in Fig.3, consist of a metal blade with a wooden handle. The small trowels of various shapes are used for finishing and repairing mold cavities as well as for smoothing over the parting surface of the mold. The usual trowel is rectangular in shape and has either a round or a square end.

BELLOW: The hand operated bellow, as shown in Fig. 5, is used to blow loose particles of sand from the cavities and surface of the mold.

Figure-5: Bellow

Fig.6:

A simple lifter or cleaner

Fig.7:

A Yankee lifter

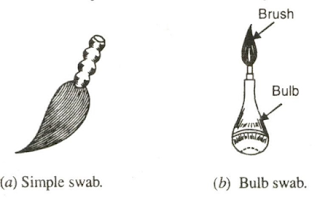

Fig.8: Swab

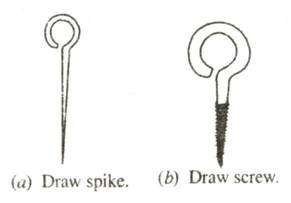

DRAW SPIKE OR SCREW: The draw spike is a pointed steel rod with loops at one end. It is driven into a wooden pattern when it is withdrawn from the sand. The draw screw is similar in shape but threaded on the end to engage metal patterns.

Fig.11:

Sprue cutter

Fig.12:

Shovel

MAJOR COMPONENTS OF SAND MOLDS

- The mold itself, which is supported by a flask. Two piece molds consists of a cope on top and a drag on the bottom. The seam between them is the parting line. When more than two pieces are used, the additional parts called cheeks.

- The molding board is a smooth surface board made of either wood or metal on which the flask and pattern are placed when the mold is started. The board should be perfectly flat and should be reinforced with cleats on the bottom. When the mold is turned over the mold surface of the board is finished. When the mold is placed on the similar board called BOTTOM BOARD, which acts as a support for the mold until the metal is poured.

- A Pouring system or pouring cup, into which the molten metal is poured.

- A Sprue, through the molten flows downward.

- Cores, which are inserts made from sand. They are placed in the mold to form hollow regions or otherwise define the interior surface of the casting. Cores are also used on the outside of the casting to form features such as lettering on the surface of a casting or deep external pockets.

- Vents, which are placed in molds to carry off gases produced when the molten metal comes into contact with the sand in the mold and core. They also exhaust air from the mold cavity as the molten flows into the mold.

- The runner system, which has channels that carry the molten metal from the sprue to the mold cavity. Gates are the inlets into the mold cavity.

- Riser, which supply additional metal to the casting as it shrinks during solidification. Figure 1m shows two different types of risers: a blind riser and an open riser.

MOLDING

SAND

Silica sand (SiO2) - 80.8%

Alumina (Al2O3) - 14.9%

Iron oxide (Fe2O3) - 1.3%

Combined water - 2.5%

Other inert materials - 1.5%

Properties of molding sand: The

molding sand must posses the following properties:

2) Plasticity,

3) Adhesiveness,

4) Cohesiveness,

5) Refractoriness,

6) Flow ability,

7) Collapsibility.

Natural and synthetic molding sands: The natural sand is one, which contains sufficient clay as mined from the sand pit so that it can be used directly. It needs only to be tempered and conditioned. Since the natural sands have the advantages of simplicity in their preparation, handling and use, therefore these are used for most of the ferrous and non-ferrous castings.

The synthetic sand is one, which is artificially compounded by mixing sand grains and selected type of clay. These sands have the advantages of lower cost in larger volume, wide spread availability and the possibility of sand reclamation and reuse.

The advantages and disadvantages of synthetic molding sands compared with natural sands are:

|

Advantages |

Disadvantages |

|

1.

Synthetic molding sands are greater durable and will maintain more strength

than that of natural sand |

1.

Synthetic sands are workable over a narrow moisture range. |

|

2.

More uniform than natural sand results better control over foundry sand

condition. |

2.

It dries out more rapidly. |

|

3.

Free of slit of fines. This results in higher permeability, better flow

ability and considerably less water for tempering. |

3.

Preparation of synthetic sand requires more mechanical equipment. |

|

4.

More refractory than natural sand. |

4.

More skill required when patching synthetic sand molds. |

TYPES OF MOLDS

The various types of molds, according to type of

material used, are as follows:

Green

sand mold: The sand mold prepared from natural molding sand in

its green state is called green sand mold. The green sand mixture is prepared

by mixing thoroughly silica sand (80 percent), clay (10 to 15 percent) and

water (4 to 6 percent). This mixture should be properly tempered before it is

used. The green sand molds may be used for small and medium castings of ferrous

and non-ferrous alloys. Since the green sand molds contain moisture, therefore

certain defects like blow holes may occur in casting. The surface finish of

castings made in green sand molds is also not good.

Dry

sand mold: The sand mold

prepared from fine-grained sand mixed with suitable binder is called dry sand

mold. These molds must be backed in an oven. The dry sand molds are stronger

and may be handled more easily with less damage. These molds are mostly used in

small and medium-sized casting. For large castings, the dry sand molds may be

made in sections. These molds may be used for many alloys but are more common

in casting of steel.

Loam

mold: The mold made with loam sand (a mixture of sand and

clay) is called loam mold. The loam sand also contains fire clay or ganisters.

The loam molds are similar to pit molds and are used for large work where the

pattern required will be too expensive to make. The mold is first built up with

bricks or large iron parts. These parts are then plastered with a thick loam

sand mixture consisting of silica sand (22 volumes), clay (5 volumes), coke (10

percent) and moisture (18-20 volumes). The shape of mold is obtained by either

with sweep or skeleton patterns. The mold is then allowed to dry thoroughly so

that it resists the heavy rush of molten metal and withstand heavy temperature.

Since much time is required to make a loam mold, therefore these are not

extensively used.

Skin-dried

mold: The sand mold with a dry sand facing and a green sand

backing is called skin-dried mold. These molds may be used for casting all

ferrous and non-ferrous alloys. These molds are more commonly used for large

molds. The skin-dried molds are less expensive to construct than dry sand molds

but more expensive than green sand molds. It requires less floor space and time

for comparable sizes of dry sand molding. The skin-dried molds are not so

strong as dry sand molds.

Metal

molding: The mold made of metal is called metal mold. The

metal molds are used in casting of low melting temperature alloys. Since

castings produced by metal molds have a smooth finish, therefore much of the

machine work is eliminated.

MOLDING PROCESS

Bench

molding: For small work, this type of molding is done on a

bench of suitable height.

Floor

molding: Large casting with difficulty in handling, the mold is

done on the floor.

Pit

molding: Extremely large castings are molded in a pit instead

of a flask. The pit acts as drag part of the mold. A separate cope is used

above it.

Machine

molding: Some of the molding operations such as ramming the

sand, rolling the mold over, forming the gate and drawing the pattern can be

done by these machines much better and more efficiently than by hand.

To

illustrate a few fundamentals in molding the following exercise is given. (The

pattern is a flange):

- Prepare enough sand to fill the flask when removed.

- Place drag on molding board, joint side to the board, guide pins pointing downward.

- Place pattern, large side down, in drag.

- Riddle ½ in, sand over the pattern.

- Fill drag with sand and peen all around with bench rammer, keeping at least 2" away from pattern. Don’t ram over pattern.

- Refill drag, peen all over, ram again and put off a lower.

- Strike off excess sand to the level of drag using straight-edge.

- Vent around and over pattern with vent wire.

- Roll handfuls of loose sand over mold. Rub bottom board over sand in order to make it bear evenly. This is absolutely necessary. If the bottom board does not fit snugly against the sand; the mold will crack.

- Roll drag over and remove molding board.

- Place cope on drag, with binges and latches corresponding.

- Shake parting compound over joint.

- Flow parting compound off pattern with the billow.

- Place gate pin 2 in from side of pattern.

- Riddle ½ in sand over pattern.

- Refill cope, peen all over, refill again and butt all aver.

- Fill cope with sand and peen all around close to flask.

- Strike off and level with top of cope.

- Vent over pattern with vent wire.

- Remove gate pin and cut poring basin into the cope.

- Remove cope, blow excess parting compound off the drag.

- Swab around pattern, Rap and draw pattern.

- Cut gate in drag ½" deep, 1" wide and remove any loose sand from the mold.

- Put board on outside of cope and lay it down flat, board underneath.

- Shake blacking on gate and on mold surfaces in cope and drag.

- Stand cope on its side molding board in place. Remove board and clean pouring basin.

- Dust blacking in pouring basin.

- Put cope on drag in its original position.

- Set mold level on the floor carrying it with bottom plate held firmly in place.

- Uncover pouring basin and place suitable weight on cope to hold it down against the lift of the molten metal.

PATTERN

Pattern:

It

is the model of desired casting with exactly same shape and size with or

without the addition of allowance and core prints.

Pattern

may be made of wood, metal, plaster or plastic. The type of pattern material

chosen depends on the design of the casting, the number of castings to be

produced, method of production, the degree of accuracy and surface finish

required.

PATTERN MATERIALS

WOOD PATTERN: It is widely used

material for patterns. It is used when small number of castings is to be

produced. The wood as a pattern material has the following advantages and

disadvantages.

Advantages:

(b) It can be easily worked and shaped as desired,

(c) It can be cut and fabricated into numerous forms by gluing, bending and carving,

(d) It is easily planned and sanded to smooth surface and can be preserved fairly for a long time with shellac.

Disadvantages:

(b) Since it cannot withstand the continuous abrasive action of sand, therefore it is unsuitable for repetition work.

METAL PATTERN: Metal pattern are

made of brass, bronze, white metal, cast iron and aluminum alloys etc. When

large number of castings is required, the pattern is made of a metal.

Small patterns are frequently made of brass or bronze. They draw well from the mold and maintain a smooth finish because of their resistance to atmospheric corrosion. Certain alloys called white metals because of their low shrinkage characteristics. They are safer and less durable by they are less expensive to produce because of the casting of finishing.

Patterns

allowance: Some allowance should be considered to make the

patterns.

Shrinkage allowance for:

Steel 1/4"

per foot

Cast iron

1/10" per foot

Aluminum

9/32" per foot

2. Finishing allowance: It is the tolerance in dimension provided in the added to make a pattern for machining to surface of casting.

Machining allowance depends on (1) Machining method, (2) Characteristics of metal, (3) Size and shape of the casting, (4) Method of casting.

3. Draft allowance: To facilitate the withdrawal of a pattern from a mold proper draft should be applied to the pattern surface. The amount of draft on the average pattern varies from ¼ to 1 degree, depending on the method of molding.

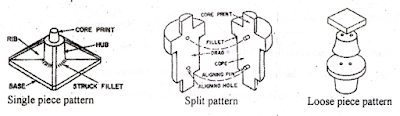

Types

of pattern:

II. Loose piece pattern

III. Split pattern

IV. Match plate pattern

V. Gated pattern

CORE

Core:

Core is a sand body form by the pattern or core box, which placed in the mold

cavity to get hold slot, or cavity in any require in casting.

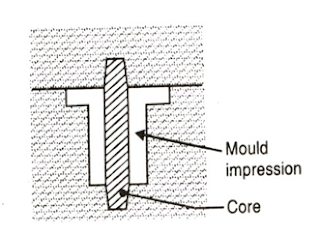

The cores used in foundries are classified according to their shape and position in the mold as under:

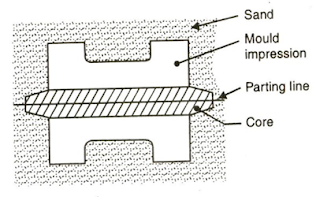

Horizontal core: It is the most common type. It is usually in a cylindrical form laid in the mold horizontally. The ends of the Core Rest in seats provided by the Core prints on the Pattern.

Figure-15: Horizontal core

Figure-16: Vertical core

Balance core: A balance core has a single core print and produces a single opening in casting.

Figure-17:

Balance core

CORE SAND: Various qualities of sand are used in making cores depending on the properties in the core. High silica sand containing very little if any clay bond is generally used. In choosing core sand the foundry men consider grain size distribution and shape mineralogical composition. A high percentage of quartz is desirable because quartz does not fracture when exposed to heat.

CORE BINDERS: The core binders serve to hold the sand grains together and impart strength, resistance to erosion and to breakage and degree of collapsibility. They may be classified as organic and inorganic binders. The organic binders are combustible and are destroyed by heat. Hence they contribute a degree of collapsibility to the core sand mixture. The inorganic binders are not combustible and may have considerable strength at high temperatures, may have resistance to erosion and may be relatively non-collapsible, depending upon their nature.

CORE BOXES: A core box is essentially a type of pattern made of wood or metal in which sand is rammed or packed to form a core.The core box is made exactly to the shape and size of the core required. Several types of core boxes are used according to the shape of the core.