Abstract

Firstly, we measure the diameter of the spring several times using slide calipers and take the

mean value. Then we attach it to a stand. Diameter of the wire is then measured by screw gauge.

Then twice the diameter of wire is substracted from outer diameter of spring to get inner

diameter and average of that two is taken as diameter of spring.[1] Now a certain mass is hung

from spring. Mean position is marked. We lift it and let go causing a vertical oscillation. We

measure the time for 50 oscillation and record the corresponding data. The same process is

repeated for 5 times. Then graph plotting (T^2

vs M) ,calculation of k and and error analysis is

done based on the obtained data.

Introduction

Spring constant is a

characteristic of a spring which is defined as the ratio of the force

affecting the spring to the displacement caused by it. Usually denoted with the

letter "k" in formulae, as in the formula F =k − x , where "F"

is the force applied and "x" is the displacement. Hooke's Law states

that the restoring force of a spring is directly proportional to a small

displacement.[2] In equation form, we write,

Where x is the size of the displacement. The proportionality constant k is specific for each

spring. The object of this virtual lab is to determine the spring constant k.[3]

The effective mass of the spring in a spring-mass system when using an ideal spring of

uniform linear density is 1/3 of the mass of the spring and is independent of the direction of the

spring-mass system (i.e. horizontal, vertical, and oblique systems all have the same effective

mass). This is because external acceleration does not affect the period of motion around the

equilibrium point.

We can find the effective mass of the spring by finding its kinetic energy. This requires adding

all the mass elements' kinetic energy, and requires the following integral, where u is the velocity

of mass element :

Modulus of Rigidity, G: Modulus of rigidity of a spring is

also known as the spring constant (Shear Modulus) is the coefficient of

elasticity for a shearing force. It is defined as "the ratio of shear

stress to the displacement per unit sample length (shear strain)".Modulus

of Rigidity can be experimentally determined from the slope of a stress-strain

curve created during tensile tests conducted on a sample of the material. The

definition of Modulus of Rigidity: the ratio of shear stress to the

displacement per unit sample length (shear strain).[5]

Theory

In this experiment a spring is suspended vertically from a clamp attached to a rigid frame work

of heavy metal rods. At the bottom end (which is the free end) of the spring a load of

mass, m0 is suspended. So the force acting on the spring is the weight m0g of the load

which acts vertically downward and the spring gets extended. Due to the elastic property

of the spring, it tries to regain its initial size, hence applies a counter force on the load,

which is called the restoring force of the spring. According to Hooke’s law, magnitude of this

restoring force is directly proportional to the extension of the and the direction of this restoring

force is always towards the equilibrium position.[6] If k is the spring constant of the spring and

the extension of the spring, then restoring force = - kl

Let the spring is in equilibrium with mass mo

attached as in Fig. 02 (a), and so we can write

m0g = kl

=> l=g/k mo … … … …

… … … … … … … … …(1)

Here,

k is the

spring constant and g is the acceleration due to gravity.

Equation (1) is an equation of straight line slope of this

line is given by

Slope = g/k,

K = g/slope

… … … … … … … … … … … … …(2)

We can plot l vs mo graph and determine its

slope to determine k

If the load is slightly pulled down and released, the

spring will oscillate simple harmonically. Suppose, at time t the velocity of

the load is v and the spring is compressed by a distance y above the point C.

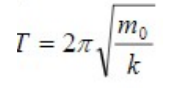

As we know from our earlier schools if the mass of the spring were negligible

then the period of oscillation.

That would be given by,

Due to the mass, m of the spring an extra term m′ will be added with the mass of the load mo in

the above mentioned equation. So, the period of oscillation is,

m′ is called to be the effective mass of the spring. It can be showed that m′ is related with the

mass of the spring by following equation,

m' = m/3 … … …. …. …. … … … … … … … … … … … (4)

So, from equation (3), we get,

For different mass, mo of the load we find

different periods of oscillation, T. If we draw a graph by plotting m0

along X axis and corresponding T2 along Y axis, it will be a

straight line. The point where the line intersects the X axis, its y-coordinate

is 0, i.e. T2 = 0 there. We can find the X coordinate of the point,

(i.e. the value of mo at that point) by putting T2 = 0 in

the above mentioned equation,

That means x coordinate of the point is equal to the

negative value of the effective mass. So, if we draw a T2 vs. mo

graph, it will be a straight line and its x-interception gives us the effective

mass of the spring.

If n is the rigidity modulus of the material of

the spring than it can also prove that,

Where,

N = Number of turns in the spring

R =

Radius of the spring

K = Spring constant

r = Radius of the wire of the spring

Apparatus

1. A

spiral spring

2.Convenient

masses with hanging arrangement

3.Clamp

or a hook attached to a rigid framework of heavy metal rods

4. Weighting

balance

5. Stop

watch and

6. Scale

Experimental Data

|

No. of observation

|

Loads mo in gm

|

Extension in cm

|

No. of vibrations

|

Total time in sec

|

Period T in sec

|

T2

|

|

|

0

|

15.9

|

|

------

|

------

|

-----

|

|

1

|

50

|

6.1

|

50

|

50.80

|

1.016

|

1.032

|

|

2

|

100

|

12.6

|

50

|

56.77

|

1.1354

|

1.289

|

|

3

|

150

|

18.9

|

50

|

61.03

|

1.2306

|

1.514

|

|

4

|

200

|

25.3

|

50

|

68.72

|

1.3744

|

1.888

|

|

5

|

250

|

31.2

|

50

|

70.59

|

1.4118

|

1.9931

|

Calculation

Spring constant, K = Mg = 7229.508 dynes/cm

From graph (2) effective mass = 40 gm

a) No.

of turns N in the spring = 162

b) Radius

of the spring, R = (D+d)/4 = (2.785+2.575)/4 = 1.34 cm

c) Radius

of the wire of the spring, r = 0.65975 cm

Percentage error

Result

The spring constant of a given spiral spring is

7229.508 dynes/cm and effective mass is

40 gm. And the rigidity modulus of the material of the spring is 8.8439 × 10^11 dynes/cm with an error of 6.5% .

Discussion

Measurement

of radius of wire/spring and weight-

1. Some instrumental error may arise if main scale

zero doesn’t coincide with circular scale

zero. That have been taken care of by adding or substracting the error.

2. If the wire is not uniform then readings have to

take at different points and mean of them is

the best reading.

3. While hanging the weights that should lie along

the axis of spring. This doesn’t occur during experiment.

Measurement

of time period -

1. Firstly

measurement of time period is not accurate due to personal observation error.

2. Oscillations

should occur in vertical plane but it oscillates little in a horizontal plane

also.

Conclusion

In the experiment, there are some important apparatus.

These apparatus are very useful to find out the exact value of spring material.

Spring constant can be measured accurately by following the precaution of these

apparatus. There will be small amount of error if the value is taken

accurately.

References

[1].https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0ahUKEwj60aSM8sfVAhWLrY8KHeUTCbIQFggnMAA&url=http%3A%2F%2Fwww.cmi.ac.in%2F~souvik%2Flab3%2Fspr.pdf&usg=AFQjCNGRt2dLUl2AUz oE9PnZ-ZukensdYg

[2].https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=2&ved=0ahUKEwj60aSM8sfVAhWLrY8KHeUTCbIQFggvMAE&url=http%3A%2F%2Fkamaljeeth.net%2Fnewsite%2Findex.php%3Froute%3Dproduct%2Fproduct%2FgetProductAttachmentFile%26attachment_id%3D301&usg=AFQjCNHiQGpibxIrHE3VmtBLZXEl-PLw4Q

[3]. https://www.coursehero.com/file/8113988/EXP4/

[4].http://www.markedbyteachers.com/as-and-a-level/science/the-experiment-involves-thedetermination-of-the-effective-mass-of-a-spring-ms-and-the-spring-constant-k.html

[5]. https://mainulgub.files.wordpress.com/2016/06/scan0002.pdf

[6]. http://ncert.nic.in/ncerts/l/kelm105.pdf